|

|

Construction Methods for Pile Foundations |

|---|---|

Pressing and extracting +38 095 8483234

|

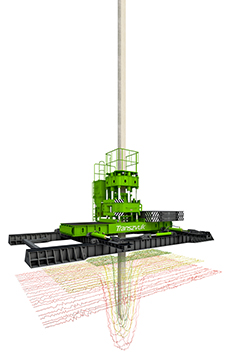

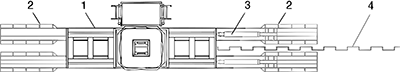

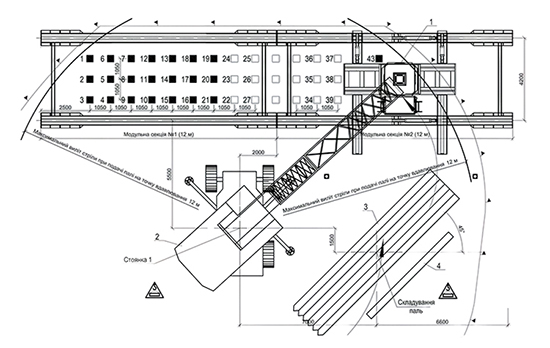

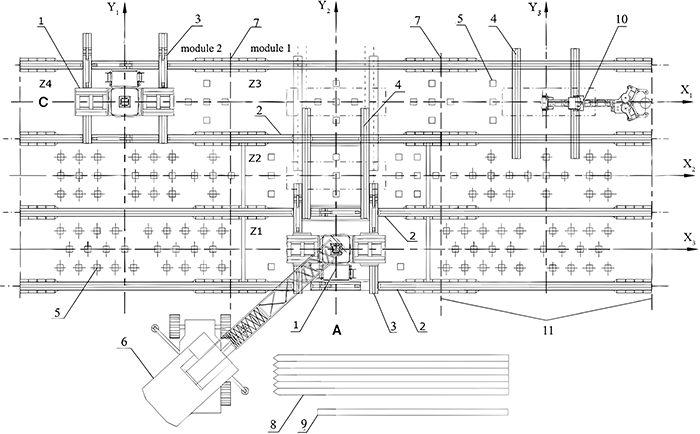

To unify and typify the technological solutions, the authors proposed to classify the existing methods of piling works according to the technological sequence of pile installation processes and positional displacements of the piling equipment. It refers to the ability of the equipment used in piling works to complete the installation process without the need for requiring any readjustments or interruptions to the main technological process: pile pressing - piling machine displacement. The classification distinguishes 1) Point; 2) Lineal (X); and 3) Coordinate (X, Y) methods. Based on this classification, three piling methods have been developed. For each method, an automated Piling Machine SO-450 or RSM-80 is used. To ensure maximum architectural flexibility, the geometric parameters of pile foundations for civil buildings have been taken into account in the development of these methods. 1. Point methodThe Point method (P) is based on the Piling Machine repositioning by a service crane. It is used for the installation of single piles, including the piles with increased liability, in cases where the safety of nearby buildings is critical. This method remains indispensable when piling works are carried out under conditions of maximum proximity to existing buildings (1 m for concrete piles and 0.5 m for sheet piles). Unfortunately, the productivity of the P method is low. It is one pile per hour, with 25% of the time spent pressing a 16 m long pile into the ground and the remaining 75% of the time spent on inefficient auxiliary operations such as mounting, anchoring, disassembly, repositioning of the machine by crane. 2. Lineal methodThe Lineal (L) method is based on the single coordinated positional movement of the Sheet Piling Machine along the longitudinal X coordinate, along the axis of the pile row, using fixed longitudinal skid guides 2, as shown in Figure below. This method is used for the single-row arrangement of building elements: concrete piles, tubes, sheet piles, metal profiles, etc.  Sheet piling by the Lineal method: The advantages of the Lineal method are obvious for all types of linear works, whether they are cut-off walls, sheet pile retaining walls, or landslide protection structures. Labor productivity is significantly increased compared to the Point method, but it is still insufficient for multi-row pile structures, because of the frequent need to readjust the piling equipment. 3. Coordinate methodThe Coordinate (C) method is based on the two coordinated positioning movements of the Piling Machine along the longitudinal axis, using the cross carriage 3, as shown in the figures below, Option C. It is used for a cluster and multi-row disposition of piles. The technological process for the C method uses two modules with sequential reconnection (UA Patent No.59646). It has been shown that the implementation of the C method together with the accuracy of the pile installation (position and inclination control) reduces production time and provides higher productivity. However, in a restricted working area, the sequential reconnection of modules is difficult due to the limited working area of the crane. There is a need for additional operations that increase the machining time, such as repositioning the equipment with the crane in a new working area, remounting the Slide System, and re-anchoring the Piling Machine.  Coordinate method with two modules: When the row of piles on the X-axis is completed, the main operation has to be readjusted, together with the interruption of the positioning control. The parallel installation of modules when the Piling Machine moves in the transverse direction Y does not guarantee the continuity of the modular grid system and, therefore does not allow complex automation. The flow-production method. The use of the Aggregate-Modular Piling System (UA Patent No.114055) has been proposed as a new flow-production method for pressing piles into the ground. The system consists of three longitudinal guides and two cross carriages that allow the Piling Machine to move along two axes, X and Y, as shown in Figure below, Option A. When assembling a Modular Piling System, the modules' main axes (X, Y) are controlled in relation to the modular coordination grid system of the building. This ensures correct alignment and integration of the Piling System with the building structure. In the preparation process, the longitudinal guides 2 are mounted. The main carriage 3 is then mounted on the longitudinal guides, followed by the mounting machine 1 on carriage 3. The hydraulic system of the modules is then connected to the Piling Machine and the anchor loads are installed using a service crane.  Aggregate-Modular Piling System layout for the Coordinate method: Once the anchor loads have been secured, the horizontal position of the Piling Machine is checked to complete the process. The main technological process, pile installation - piling machine displacement, is carried out inside working area Z1. Additional longitudinal guide 2 and auxiliary carriage 4 are mounted by the crane, without interrupting the main process. The coordination of the axis distance (X-Y) to the modular grid system is constantly under control. When all the piles have been installed in Z1, the Piling Machine moves to the next working area Z2. The main process is carried out. At the same time, the modular system is reassembled. The Piling Machine moves from the auxiliary carriage 4 to the main cross carriage 3 through drive cylinders. The main process is carried out inside working area Z3. Once all the piles have been installed in Z3, the Piling Machine moves to the next working area according to the desired direction. At the same time, Module 2 can be attached to the extension of Module 1, using a service crane, as shown in Figure above, Option C. When the piling is completed in the working area of Module 1 (Z3), the Piling Machine moves to Module 2 (Z4). The movement along the X-axis is performed by a method of sequentially reconnecting the modules. At the same time, the auxiliary carriage 4 can be used to mount additional equipment 10 on it: a drilling machine, a crane manipulator, mechanisms for stone columns, vertical energy wells, etc. This method offers modularity and flexibility in the configuration of different pile foundations for civil and industrial buildings and it is suitable for use in large-scale and mass construction for multi-row and continuous pile fields. It is also suitable for the complex automation of pile bases construction. |

|

Engineering Center Transzvuk, Nakhimov Lane, 6, 65014 Odesa, Ukraine. Phone: +380674861177 | E-mail: ECTranszvuk@gmail.com |

|