|

|

Automated piling equipment for foundation engineering |

||||||||

|---|---|---|---|---|---|---|---|---|---|

Pressing and extracting +38 095 8483234

|

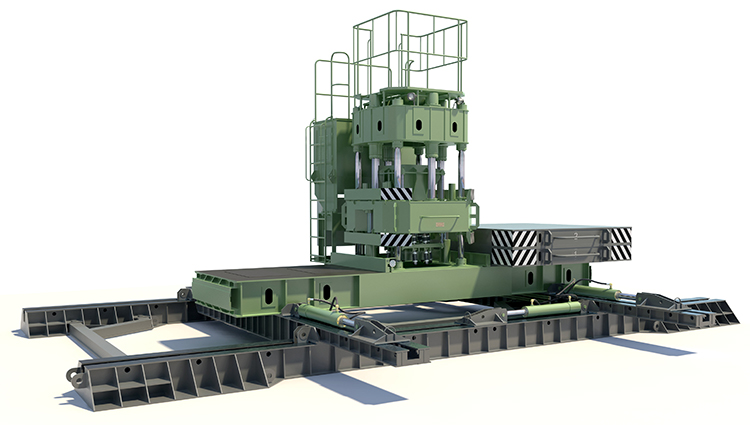

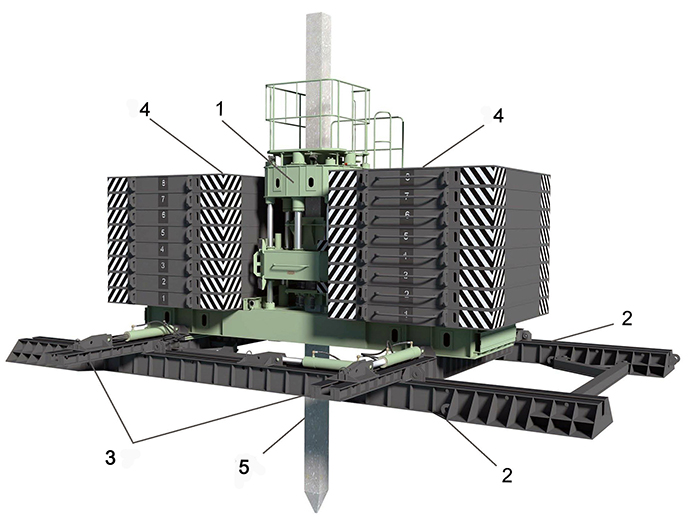

Aggregate-Modular Piling SystemThe development of an automated construction process for pressing precast pile elements into the ground begins with the creation of the Aggregate-Modular Piling System (UA Patent No.114055). This piling system was developed by the Engineering Center Transzvuk in Ukraine. It is used for the construction of pile foundations and sheet pile structures for civil and industrial buildings. The Piling System, as shown below, consists of the original Piling Machine of pressing type and a Modular Coordinating Slide System.  Aggregate-Modular Piling System The concept of using an Aggregate-Modular Piling System (AMPS) allows for precise, biaxial (X-Y) controlled repositioning of the Piling Machine, without the need to remount and re-anchor and without interrupting the main technological processes: pile installation - piling machine displacement. Hourly output is 4 concrete piles. Technical specifications are given below.

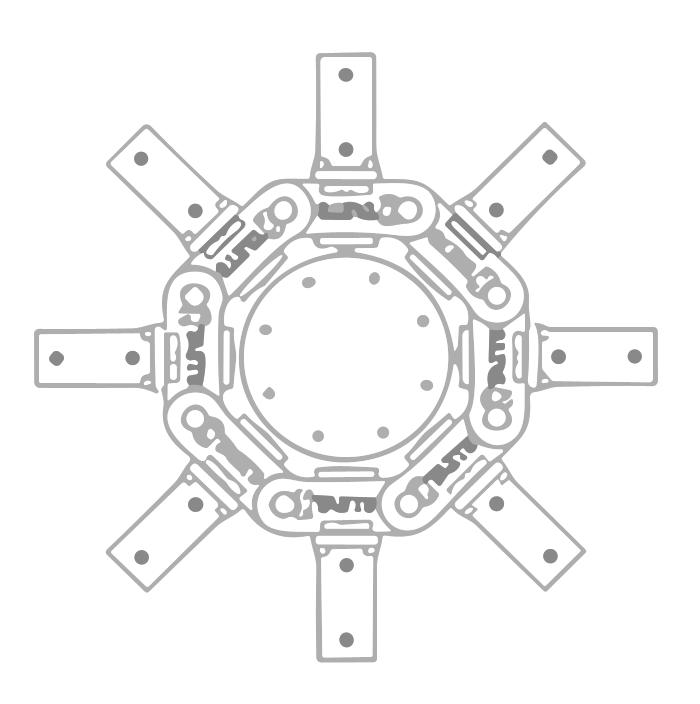

Hydraulic Piling MachineThe hydraulic Piling Machine (UA Patent No.77005) is intended for pressing into the ground precast construction elements: concrete piles with cross-sections up to 450×450 mm, sheet piles not more than 500 mm width, and metal pipes. The pressing force of the Piling Machine is up to 2300 kN. It works on the principle of self-centering the pile utilizing a side wedge-operated clamping system and cyclically pressing a pile into the ground in manual or automatic mode. The pile pressing force (soil resistance) is controlled by the machine's hydraulic system. The Piling Machine is a gravity type and is anchored with metal loads by a service crane. The total weight of the loads can be up to 200 tonnes and is determined by the soil resistance. The weight of the machine is 14.3 tonnes. It is the best performance for existing equipment in terms of the pressing force of the piling machine concerning its weight. This feature is important when working space is limited. The pile to be installed is loaded into the machine by the service crane. A metal inventory tool is used when installing piles below ground level (up to 12 m). The team comprises an operator, a crane operator, and two slingers. Piling Machine S0-450 Modular Coordinating Slide SystemThe Modular Coordinating Slide System (UA Patent No.62369) is a floor-type hydraulic push-pull system consisting of the main (aggregative), auxiliary longitudinal module (fixed), and a cross carriage (movable). It has been designed following the general principles of the international standard for building construction (ISO 2848:1984 Building construction - Modular coordination - Principles and rules). This ISO specifies the objectives of modular coordination and defines the dimensions of buildings, foundations, and the positioning of their components, piles, equipment, and assemblies. The modules used are identical and interchangeable, allowing them to be connected in various combinations. slide movement controlled along two axes. The Modular Slide System can also be used to move heavy equipment or structures (up to 350 tonnes) in both longitudinal and transverse directions. Specific ground pressure when using 1 module: 15.7 tonnes when using 2 modules: 8.3 tonnes per square meter. This makes it possible to work on slopes and sites with weak or water-saturated soils. |

||||||||

|

Engineering Center Transzvuk, Nakhimov Lane, 6, 65014 Odesa, Ukraine. Phone: +380674861177 | E-mail: ECTranszvuk@gmail.com |

|||||||||